Belt-Winding Cores – entire industries revolve around them

Since 1955, Souhegan Wood Products has been a global leader in the production and distribution of winding cores. Also known as extruded shells, our rugged cores provide unrivaled strength and internal support for a broad range of rubber and industrial belt as well as woven and non-woven textiles during winding, unwinding, and transport.

SWP STANDARD CORES

The strong, reliable backbone of industries around the globe

Sturdier than lumber or cardboard and lighter than steel, Souhegan Wood Products compressed wood particle cores have earned best-in-class status as the preferred core for the belt-winding industry. Our purpose-built cores are designed to transition easily through manufacturing, shipping, and installation – benefiting your bottom line and exceeding your expectations.

SWP CORE STRENGTHS

- Resist splitting

- Tremendous crush strength

- High impact resistance

- Lightweight

- Easy to implement

- Cut to desired length

- Materials can be quickly attached and wound at high speeds

- Suitable for sustained use

- Can be custom manufactured

(e.g. variable lengths, diameters, hole configurations) - Can be used as-is or enhanced

PAPER-WOUND

Versatile, high-strength reinforcement

KEY FEATURES

- Solid paper tube sheath around standard core

- Variable tube thickness to meet your application’s target strength

- Adds beam and hoop strength without added weight

- Clean, dust-free surface

- Gives core a finished, presentable appearance

BEST FOR

- Mid- to heavy-weight belting

- Woven and non-woven textiles

- Dust-sensitive products and facilities

- Repeat core use

WOODEN STAVES

Strength that rivals steel

KEY FEATURES

- Laminated custom-cut wood staves

- Won’t damage winding bars like steel can

- Added beam strength and durability

- Greater axial compressive strength

- Patented design

BEST FOR

- Demanding situations

- Mid- to heavy-weight belting

- In-field use

- Repeat core use

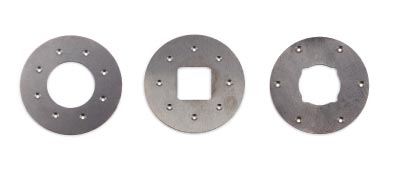

METAL END CAPS

Reinforcement for repeated use

KEY FEATURES

- Increased durability

- Protects core from abrasive and compressive damage

- Cap depth customizable from 1 to 4 inches

- Does not impede bar insertion

- Can be added to paper-wound and staved cores

BEST FOR

- Prolonged in-house use

- Cores spun on a journal or roller cradle

- Product stored on an end-support rack

- Chain-down trailer transport

COATED FINISH

A smooth, dust-free seal

KEY FEATURES

- Creates a clean surface, free of dust and particles

- Provides a more finished appearance

- Can be applied to paper-wound or staved cores

BEST FOR

- Dust-sensitive products and facilities

- Woven and non-woven materials

- End-use customers that showcase product on the core

NOTCHED

Prevent belting damage and waste

KEY FEATURES

- Patent-pending design allows belting to wrap flush against core

- Reduces profiling-through of any susceptible rubber and textile materials

- Reduces product waste

- Favored by end-use customers

BEST FOR

- Manufacturers – offer this money-saving option to your customers

- Distributors – cut costs and waste

- Winding heavyweight materials

CUSTOM CORES

Our engineers can also custom design and manufacture cores to meet specific-use demands (e.g., round holes, variable lengths).

Get your core knowledge to go.

Download our Belt-Winding Core brochure.