A history of ingenuity and strength

Souhegan Wood Products first recognized the environmental and economic value of recycling wood byproducts over 70 years ago. It all began in the early 1920s with our great grandfather, C. Randolph “Randy” Myer, who graduated from the Massachusetts Institute of Technology with a degree in mechanical engineering and an interest in finding ways to use the waste from lumbering operations. When he went to work for Long-Bell Lumber Company following his graduation, his concern for the high volume of lumber waste grew. It would be nearly 20 years before he became part of a solution.

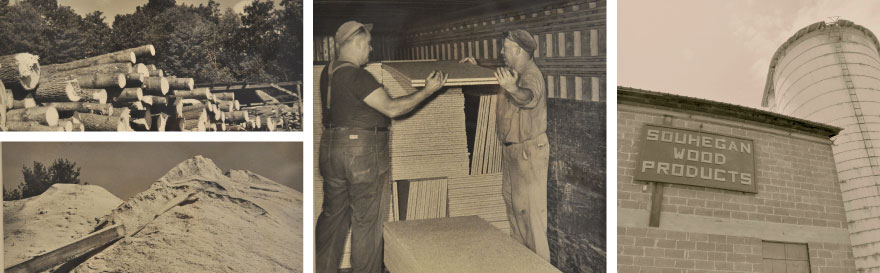

During the Hurricane of 1938, almost all the trees in Wilton, New Hampshire were blown to the ground and lay in piles all over the region. Randy bought a sawmill in town and began to turn the felled trees in to lumber that could be shipped by rail to cities and towns all over New England.

With this new lumber yard, of course, came mountainous piles of sawdust – and a unique opportunity to address an issue that had troubled Randy for decades. During World War II he made ammunition boxes and then in 1944, he developed special techniques to make use of this abundant sawdust and pioneered the manufacture of particleboard, which soon became an essential construction material during the U.S. building boom in the 1950s.

Foreseeing new applications for wood byproducts, Souhegan’s founding engineers began to design new molding and extrusion techniques with custom machinery that enabled the production of Belt-Winding Cores and other commercial and industrial products.

As we enter into our fourth generation of continuous family ownership, we have become recognized as a world leader in supplying reliable, recycled wood products to quality-conscious partners around the world.